The Science of Cool: How Cooling Coils Revolutionize Summertime Comfort

Cooling Coils, the Unsung Heroes of Summer

Coils are essential for maintaining cooler temperatures in a variety of industries. Whether it’s keeping beer cold, preserving food, controlling computer systems in data centers, or producing delicious ice cream – coils play a vital role in making all these possible! That’s why when you take a sip of that cool beverage or enjoy your favorite ice cream flavor, you can thank the coil technology that made it happen.

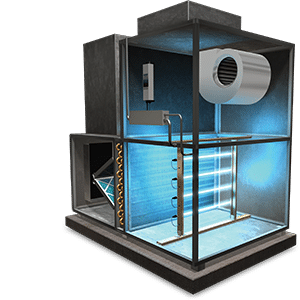

There are several different types of cooling coils, each of which is designed for specific applications, such as residential or commercial HVAC systems. All of these are designed to help you keep your environment comfortable and cool, no matter the season. Let’s take a closer look at each of the fundamental types of cooling coils.

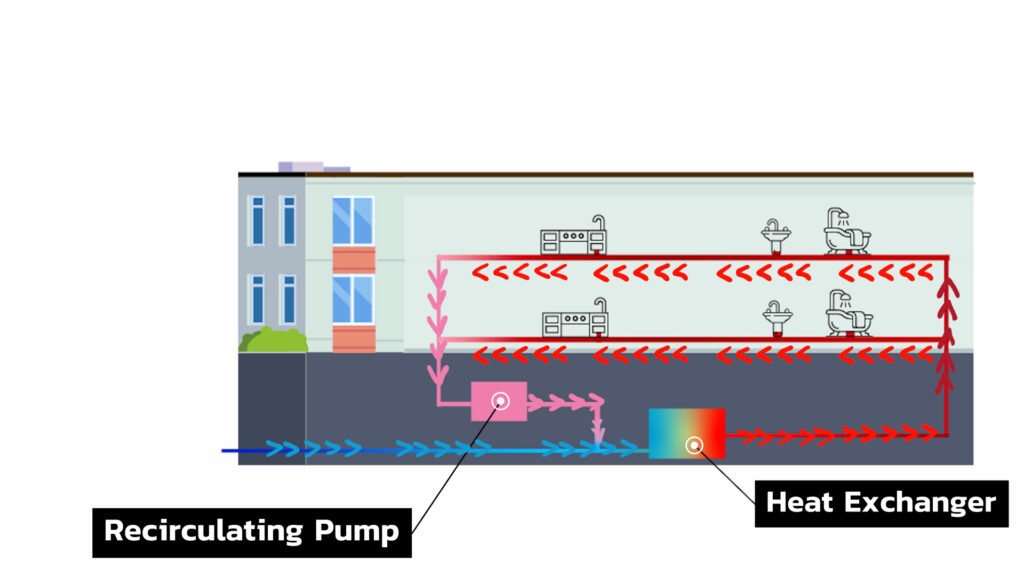

Chilled Water Coils

Chilled water coils are typically used in large commercial HVAC systems where chilled water is circulated to cool the air. These coils transfer heat between the chilled water and the air, cooling down the air before it is distributed into the building. By circulating this cooled air throughout a building, chilled water coils are able to regulate the temperature indoors, even when outside temperatures become unbearable.

Do you know the main difference between a hot water coil and a chilled water coil? Usually, hot water coils are small (1-2 rows) and chilled water coils are larger (3-12) rows deep.

Condenser Coils

Condenser coils are located in the outdoor section of the HVAC system. They receive the high-pressure, high-temperature refrigerant vapor from the compressor. As the refrigerant flows through the condenser coils, it releases heat to the outdoor air, causing it to condense back into a liquid state. This liquid then moves back into the indoor system, repeating the cooling cycle.

DX (Direct Expansion) / Evaporator Coils

DX (Direct Expansion) coils are also known as evaporator coils. Evaporator coils use refrigerant, instead of water, to remove heat from the air. As hot air blows across the coil, the liquid refrigerant inside will evaporate into a gas. This phase change allows the refrigerant to absorb heat from the air and send cool dehumidified air to the space.

So, the next time you step into a comfortably cool environment on a sweltering summer day, remember the remarkable work of chilled water coils, direct expansion coils, and evaporator coils, ensuring that you can enjoy a cool oasis no matter how high the mercury rises.

Cooling Coil Replacement in Commercial HVAC Systems

When it comes to HVAC coil replacements, there’s simply no substitute for having knowledgeable and experienced professionals on the job. These coils are critical components of your heating and cooling system, responsible for transferring heat and helping regulate temperature. As such, any missteps during the replacement process can spell disaster for your HVAC system’s efficiency and longevity.

That’s why it’s so important to trust this work to experts who know exactly what they’re doing. With their deep understanding of how these systems work, they’ll be able to seamlessly replace your coils, getting your HVAC system back up and running in no time.

The end result? A comfortable and productive environment year-round, with the assurance that your HVAC system is running optimally – all thanks to the expertise of a trusted professional.

The Need for Experienced Professionals in Coil Replacement

When it comes to reliable HVAC coil replacement, you can’t go wrong with Cooney Coil & Energy. With a reputation for excellence in the industry, Cooney Coil & Energy has been serving satisfied customers for years. Their team of experts is highly skilled in the art of HVAC coil replacement, ensuring that each and every project is handled with the utmost precision and care. Time and time again, Cooney Coil & Energy has proven themselves as a trusted and reliable choice for businesses and individuals in need of quality HVAC services. Whether you’re in need of coil replacement for your home or commercial property, put your trust in Cooney Coil & Energy and experience the difference for yourself.