STEAM

Condensate Pumps

In today’s high-demand industrial environments, the right condensate recovery solutions can make the difference between an efficient, cost-effective operation and one that constantly struggles with energy loss and downtime. That’s why Cooney Coils & Energy is proud to be a stocking distributor for Watson McDaniel, a leader in steam system solutions.

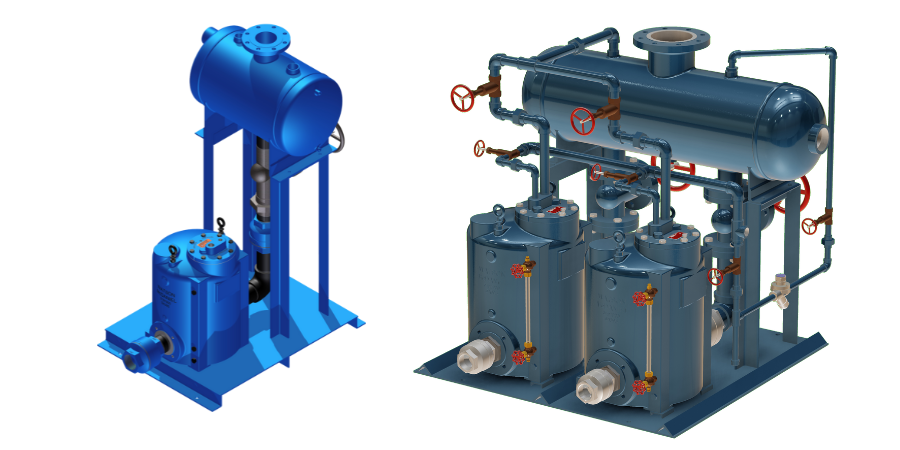

Packaged Condensate Pump Skids

Packaged Condensate Pump Skids

Introducing Simplex, Duplex, and Triplex packaged systems – they’re not just pumps, they’re game-changers! These systems use steam power to pump condensate where it belongs.

Each of these systems comes with stand-alone pumps and check valves. They also include a vented receiver tank, all set up on a strong steel base and frame. This isn’t just a bunch of parts thrown together – it’s a well-integrated, high-performing system.

With a Complete PMP system, you get everything you need in one place. It’s time to leave those outdated methods behind. Step up to the power of steam with our Simplex, Duplex, and Triplex packaged condensate systems. Don’t wait – the future of efficient condensate return is here, and it’s waiting for you!

Pressure Motive Pumps (PMPs)

Pressure Motive Pumps (PMPs) are pressure-driven pumps that return condensate back to the boiler room. They use steam pressure as the driving force.

Key Features

-

Pump Units: PMPs can be provided as individual pump units, which include a pump tank, the internal pump mechanism, and a set of inlet and outlet check valves.

-

Packaged System: Alternatively, they can be supplied as a packaged system that also includes a vented receiver mounted on a common base.

Types of Pressure Motive Pumps

- PMPC (Ductile Iron): Offers significant corrosion resistance to condensate when compared to carbon steel.

- PMPNT (Ductile Iron or Stainless Steel – Low-Profile): Suitable for lower-capacity applications.

- PMPF (Fabricated Carbon Steel): Often required by code in Chemical and Petro-Chemical industries.

- PMPSS (304L Stainless Steel – Corrosion Resistant): Can replace fabricated carbon steel tanks for extended life or when Stainless Steel is required.

- PMPBP (Carbon Steel – High-Capacity): Ideal for applications requiring large transfer rates of condensate or other liquids.

Each type of PMP has its unique advantages and is designed for specific applications, offering flexibility and efficiency in managing condensate in various industrial settings.

Steam Pump Trap Combo

In the world of steam systems, even the smallest components can make a significant impact. One such component is the pressure motive pump, a crucial element in maintaining the efficiency and reliability of your system. That’s where Watson McDaniel’s PMPT low-profile pressure motive pump comes into play.

Key Features

- Low-profile design for draining equipment close to the floor

- Patented “Snap-Assure” Mechanism for longer pump life

- Removable internal mechanism from the top while still piped in line

- Heat-treated stainless steel parts and dual compression springs made from Inconel-X-750

Optional Add-Ons

- Horizontal pipe reservoir

- Motive and vent piping

- Additional components like steam trap, strainer, and regulator

- Packaged systems with reservoir, base, and skid

- Gauge Glass, Insulation Jacket, and ASME Code Stamp available

- Steam Summary – Our short guide to steam trap, pressure reducing valves and condensate recovery pumps.

- Watson Cross Reference Guide – Looking for Spirax Sarco replacement parts? Use our guide to see what model you’ll need from Watson McDaniel

- Watson McDaniel Condensed Catalog

- View the entire Watson McDaniel Catalog

Steam Audit

Full Steam Trap Survey & System Audit

Plugged, leaking, or blowing steam traps can cost thousands of dollars in lost energy every year. Detect any waste of energy, efficiency, and dollars with a steam trap survey from Cooney Coil & Energy.

Available in Philadelphia, Pennsylvania, New Jersey, and Delaware.

American Made Condesate Pumps

We Are a Trusted Distributor of Watson McDaniels Steam Products

At Cooney Coil & Energy, we’re the go-to provider for industries in Philadelphia and the tri-state area seeking reliable steam solutions such as a Watson McDaniel steam trap. Our commitment to quality and customer service has earned us an excellent reputation in Pennsylvania, New Jersey, and Delaware as trusted distributors of Watson McDaniel steam products.

Resources

More Resources You Might Be Interested In

Steam Trap Selection

Wondering what steam trap to choose for your steam system? Worry no more! This webinar covers: types of steam traps, drip trap sizing and trap applications.

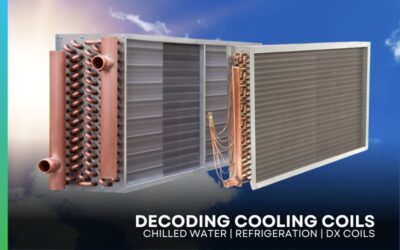

Choose Cooney as Your Replacement HVAC Coil Manufacturer

Looking for a reliable manufacturer of replacement HVAC coils? Look no further than Cooney Coil & Energy. With our expertise, wide range of coil offerings, and commitment to customer satisfaction, we provide superior performance, durability, and cost-effectiveness. Contact us today to see how we can enhance your HVAC system with custom coils tailored to your specific needs.

Cooling Coils Decoded: Your Guide to Staying Cool with Cooney Coil & Energy

We break down the different types of cooling coils, provide tips for preparing your system for the cooling season, and offer insights into choosing the right materials for your coils.