UV Light for Health and HVAC System Performance

Indoor air quality has become a hot topic in the HVAC industry. Imagine your facility is a living breathing organism. The HVAC system would be the lungs or respiratory system of the building.

Over time as buildings became more contained and tighter to conserve energy, the causes of asthma and allergy-related illness have been on the rise. The use of more recirculated air within these small spaces has posed an issue.

We’re trapped inside with biologicals and contaminants. Let’s find a way to treat them.

The History of UV Lights

UVGI has been around forever! …Well, a very long time. UVGI has been used in the food industry, water purification, and even used to disinfect hospital operating rooms in the 1930s. In the 1990s the HVAC industry began to see the benefit of UV lights. There have been many studies on the use of UV light for disinfection ASHRAE, the CDC, and WHO all recognize the effectiveness of UV lights.

Benefits of UV Light in the HVAC System

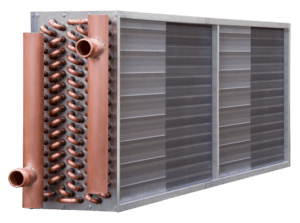

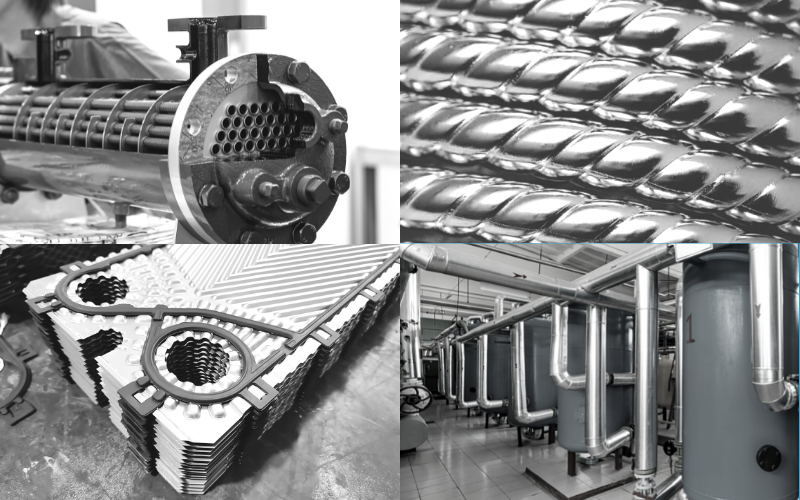

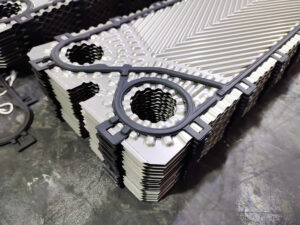

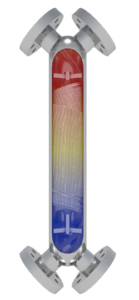

Cleaner Coils = Lower Costs + Increased Performance

Ultraviolet germicidal irradiation (UVGI) is an effective tool for improving the performance of air handler coils. This technology eliminates the build-up of biofilm on coil fins, which can reduce efficiency and increase airflow. It also helps to prevent microbial growth on surfaces like drain pans, walls, floors and blower shrouds. Installing a UVGI system in an HVAC system will reduce costs associated with pressure/chemical washing and provide continual protection against biological contamination 24 hours a day. Implementing this technology can lead to significant cost savings while ensuring peak performance of the equipment.

Improving Indoor Air Quality for Healthy Buildings

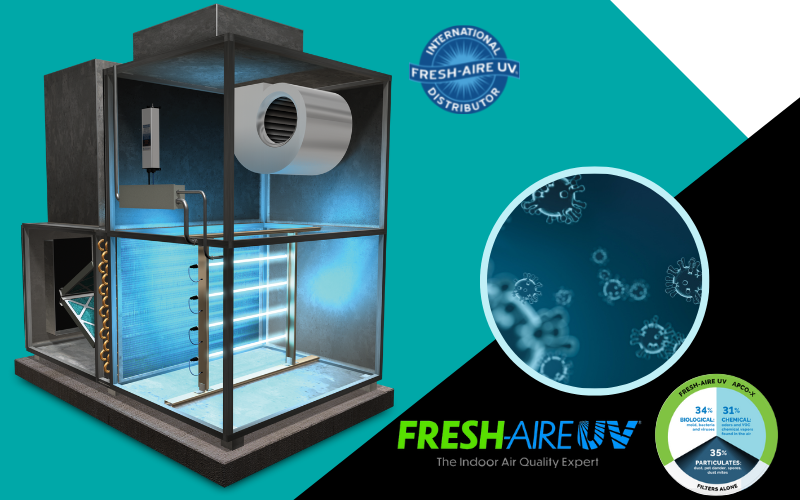

UV light is an essential part of maintaining healthy air quality in commercial facilities and can help keep occupants safe from harmful contaminants. Strategically placed UV Light systems will help mitigate the levels of contaminants in your AHU system and therefore the levels in your building’s airstream.

UV lights can reach every inch of the space and eliminate bacteria, mold, and viruses such as SARS-CoV-2. UVGI offers a chemical-free method to control biologicals that is safe and effective.

Summary

It’s clear that UVC technology is here to stay! If you’re looking for a way to reduce energy costs, improve air quality, and protect occupant health in your facility, UV Light is the solution.

Some considerations when installing UV lights are:

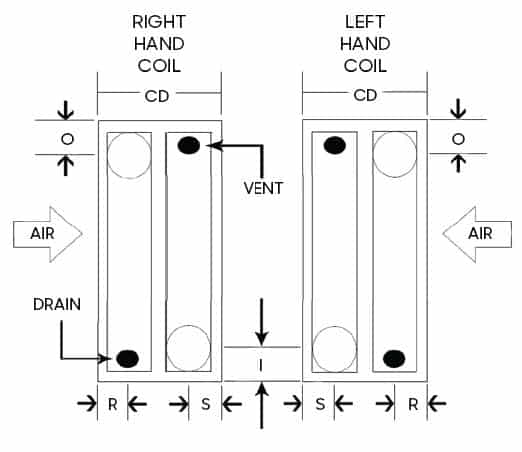

• The size of the HVAC system and ductwork

• The wattage of the bulbs that will be used

• Where they should be placed (near coils or inside ducts)

• Maintenance requirements like bulb replacement and cleaning intervals

It’s important to consult with an HVAC expert who has experience with UV light installation so you can determine the best positioning for optimal results. With proper care and maintenance, UV lights can last for many years and provide effective protection against airborne microbes, dust mites, mold spores and other allergens, as well as reducing energy costs.

If you’re concerned about indoor air quality in your facility, UV light is an effective, cost-effective solution that can help improve health and system performance over time. Contact our experts today at info@cooneycoil.com or give us a call at (610) 783-1136!