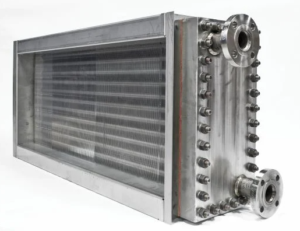

Choose Cooney as Your Replacement HVAC Coil Manufacturer

Expertise in Custom HVAC Coil Manufacturing

When it comes to keeping your HVAC system running efficiently, having high-quality replacement coils is crucial. Cooney Coil & Energy stands out as a trusted partner in this field.

Our company began with a specialized focus on HVAC coil replacement. Over the years, we’ve gained extensive hands-on experience by climbing into air handlers and directly replacing coils ourselves. We have experience in the field that allows us to effectively solve performance and reliability issues. This makes us a dependable option for custom replacement HVAC coil manufacturing.

Cooney Coil & Energy specializes in the manufacturing of custom coils tailored to specific system requirements. Utilizing advanced technologies and premium materials, Cooney ensures that each coil meets the highest standards of performance and durability.

We Know HVAC Coils

Choosing the right replacement coils for your HVAC system can significantly impact its efficiency and longevity. Cooney Coil & Energy is a leading name in this field, offering both OEM and custom HVAC coil replacements. We provide high-quality replacement heating and cooling coils for major brands like Trane, Carrier, Daikin McQuay, American Standard, York, and Heat Craft.

Customization is at the core of our business. We offer various types of replacement coils for different applications. This allows us to cater to unique customer needs while ensuring optimal system performance.

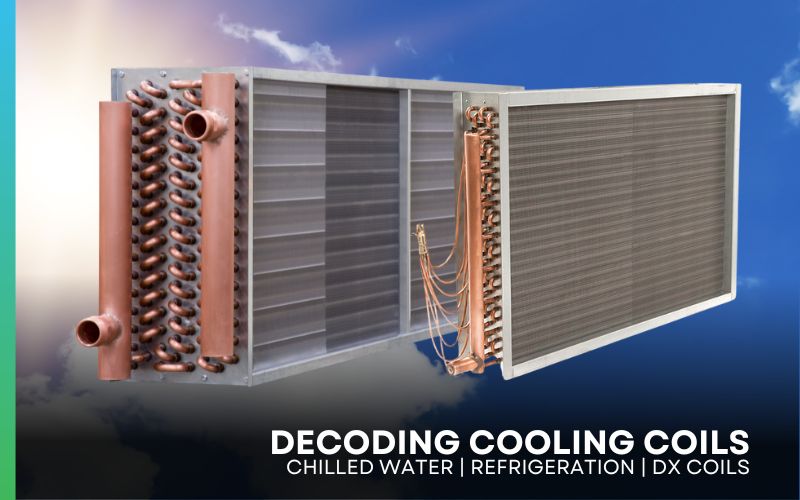

What Fin & Tube Heat Exchangers We Offer:

- Hot Water Coils: Used for heating with hot water.

- Chilled Water Coils: Designed for cooling with multiple row configurations.

- Steam Coils: Steam distributing (“non-freeze” coils) and standard steam coil for steam heating and process applications.

- Condenser Coils: Designed for your precise refrigerant application.

- DX / Evaporator Coils: Standard, interlaced, multi-circuit configurations and face split designs available to support your HVAC system.

- Sectional Coils: For when you can’t fit a coil through the door, modular coils to fit into tight spaces and reduce installation cost.

- Microchannel Coils: Drop-in replacements for York and Carrier Chillers. Made in the USA backed by a 5-year warranty.

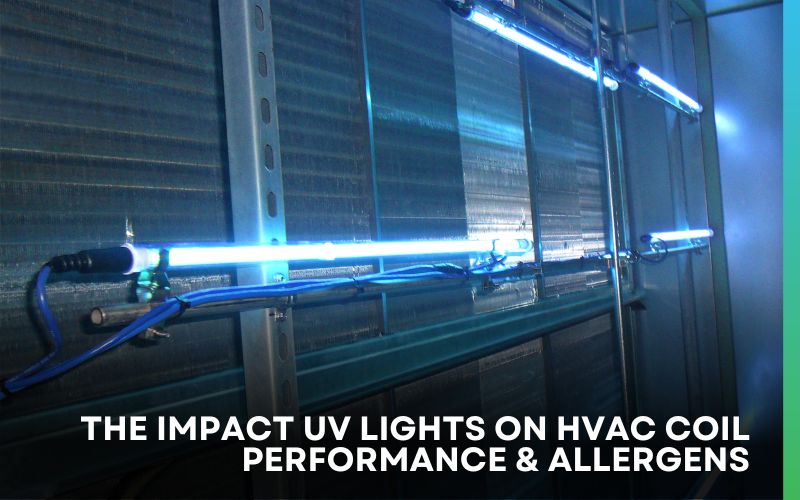

- Freeze Protection: Our Freeze Block coils are designed to prevent burst coils.

- Smart Coils: Notify your building automation system when coils start freezing, preventing damage.

We offer a variety of coils for various HVAC systems. This makes us the go-to for all your replacement coil needs. Our team will work closely with you to understand your needs and find the best solution for your system.

HVAC Coil Capabilities

Discover the full range of our top-tier HVAC coil offerings and services by downloading our capabilities line card.

Real Experience, Real Results

We’ve worked in the field with HVAC systems, solving problems where they happen. This experience means we know what works and what doesn’t. Here’s how we ensure our customers get the best:

- Site Visits: We come to your site to identify and fix any HVAC issues and provide recommendations to improve system efficiency and reliability.

- Quick-Ship Program: Fast replacements for emergencies to keep things running smoothly.

- Expert Help: Our engineers and specialists are available to help improve system performance and create solutions.

OEM &

Trusted by Customers

Facility managers, contractors, and engineers trust us to help with heat transfer. We focus on understanding their needs and providing effective solutions. With Cooney Coil & Energy, you get more than just HVAC replacement coils; you get a partner dedicated to your success.

Contact Us to see how we can help your HVAC system perform at its best.