With the current boom of craft breweries in the United States, there has never been more variety in the marketplace. You can find anything from a simple light lager to an IPA that tastes like your favorite childhood marshmallow cereal. This wide variety of beer and various sizes of breweries means cooling equipment must be tailor-made to meet individual brewery needs.

Advancement in Heat Exchange Technology

Did you know that the craft of brewing beer is over 1000 years old and dates back to the Egyptians? Before modern-day heat exchangers or wort chillers existed wort was cooled in a coolship or a large shallow vessel that must be stirred throughout a whole night. Advancements in technology have cut cooling time significantly. A high-end heat exchanger can cool the wort down in less than 45 minutes. Heat exchangers can also do a lot to improve quality, production, and efficiency at your brewery.

Maintaining Tight Temperature Control

Brewing can be complex and requires tight temperature control throughout the process. If the wort is not cooled quickly, dimethyl sulfide (DMS) can continue to produce, resulting in a tainted flavor. The formation of bacteria is another concern when it comes to flavoring and sanitation of the beer. With an effective heat exchanger, rapid heating and cooling will reduce bacteria and contaminants preventing alteration of the brews one-of-a-kind taste.

The quick cooling of wort not only helps to produce a better tasting product but helps increase production. When a heat exchanger is properly sized, the wort can be ready for fermentation in less than 45 minutes. Quicker cooling, faster brew, and increased production potential.

The key to an efficient brewery is recovering the water used in the brewing process. After cooling takes place hot water exits the heat exchanger. If this water is recovered it can be reused to heat cool water entering the building which can increase energy and water savings.

What Type of Heat Exchanger is Best For My Brewery?

With so many benefits, upgrading your brewery’s heat exchanger can pay for itself in less than a year. So where should you begin when selecting a heat exchanger? First, there are a few types to consider:

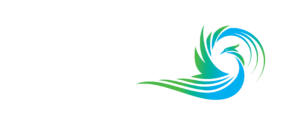

//Plate & Frame

- Utilizes metal plates to transfer heat between two fluids

- Suitable for fluid

//Shell & Coil

- Tube bundle consists of closely pact layers of helically corrugated tubes layered in a crisscross pattern

- Fluid flows through the tubes while another fluid flows through the shell and the heat exchange occurs through the tube walls

- Suitable for steam or fluid

//Shell & Tube

- Commonly known as “counterflow”

- Consist of a shell with a bundle of tubes inside

- Fluid flows through the tubes while another fluid flows through the shell and the heat exchange occurs through the tube walls

- Suitable for steam or fluid

The A-Line plate & frame systems from AIC offer a reliable cost-effective way of attaining heat transfer. Double-walled options are available to avoid cross-contamination in the case of a failure. The A-Line units can also be disassembled to adjust plates and clean. Note that these units do require floor space and that should be considered when selecting a heat exchanger.

Shell & Coil, more specifically JAD systems are constructed of welded 316L stainless steel which makes them durable and ideal for sanitary applications. The shell & coil’s tube design allows for a high heat transfer area in a small space. The vertical design and angled connections are perfect for breweries needing heat exchange in tight spaces. These units are easy to clean in place and offer the benefit of less maintenance because the larger gaps are less prone to fouling and there are no gaskets.

If your process requires copper equipment for specialized brew taste, the Cobrex shell & tube heat exchanger is for you. Doubled walled copper construction avoids cross-contamination. These units are also easy to clean in place and resistant to fouling. The Cobrex, like the JAD, features a vertical design for a small footprint.

From Nano-Breweries to Commercial Brewhouses Cooney Coil can Help!

Every project and each brew remain unique. If you’re a small single-batch brewery or a large commercial facility, we can help! Having a dedicated Cooney Coil specialist that can outline equipment capabilities will help you achieve the best performance and efficiency as possible. If you aren’t sure what model is best for you, we’d love to come to perform a site visit where we will evaluate energy consumption, process bottlenecks, and space-saving opportunities.

Contact us at 610-783-1136 to schedule a site visit or request a quote below!