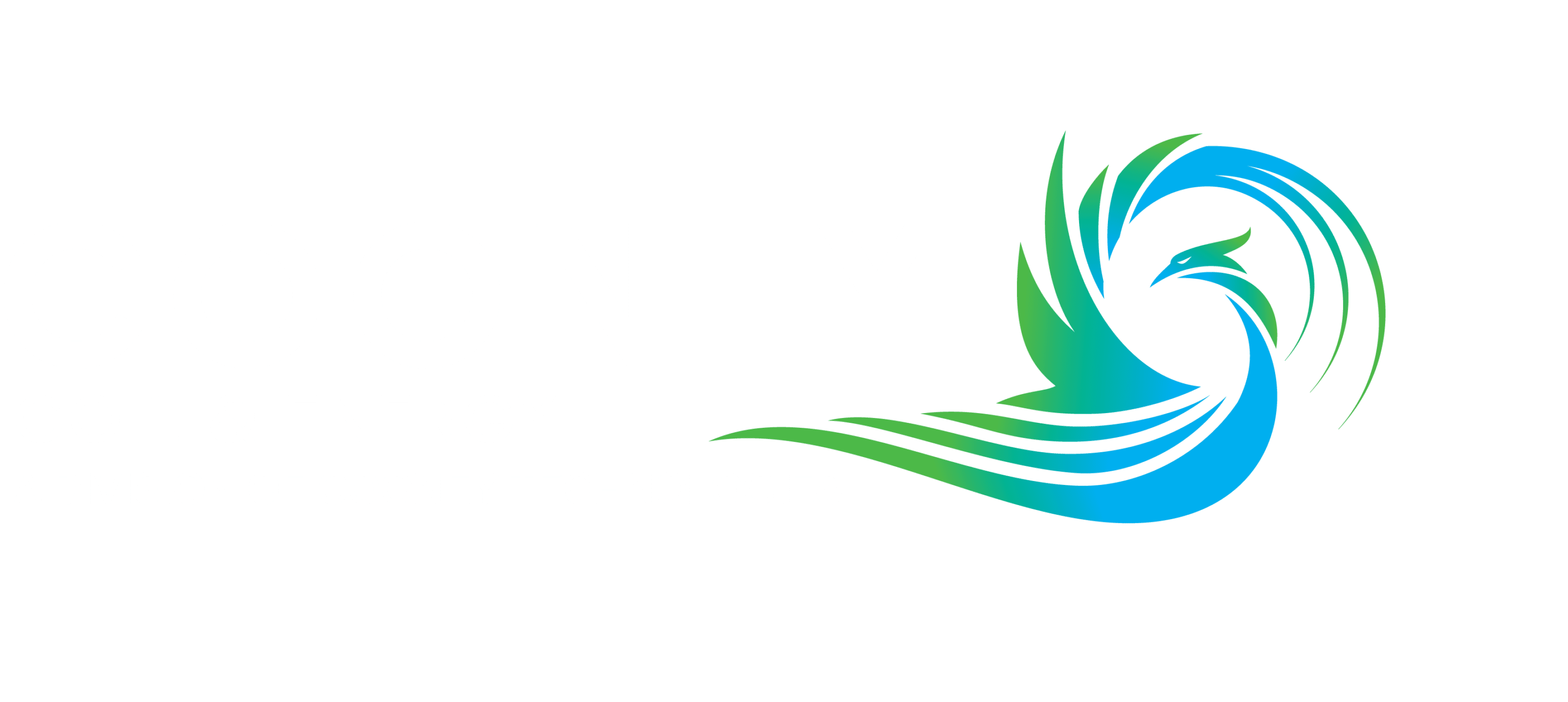

Get Ready for Winter: Tips for Inspecting HVAC Coils

Don’t Get Caught Off Guard This Heating Season – Get Your HVAC Coils Ready Now With This Essential Checklist

With winter just around the corner, it is essential to make sure your HVAC coils are well-protected and in good working order. From corrosion to freezing, there are a series of factors that could lead to performance and reliability issues if you don’t inspect and properly prepare your system for the cold months ahead. To help you get ready, this blog post will provide an overview of common HVAC coil issues, helpful products and considerations for protection, along with our services to ensure everything runs smoothly all winter long.

The Importance of Summer Preventative Maintenance for the Heating Season

There is a saying in the HVAC industry: “An ounce of prevention is worth a pound of cure.” Ignoring preventative maintenance in the summer can lead to severe problems in the winter when you need your heating system the most. Conducting regular summer preventative maintenance checks is essential to ensure your heating coils function optimally during the colder months.

Preventative Maintenance (PMs) for your HVAC coils usually takes around 2-3 days to complete. This time is well invested as it ensures your system runs smoothly when temperatures drop. Ignoring this could lead to longer, unexpected downtime in the middle of winter.

Additionally, industry lead times can average 4-6 weeks, making it crucial to start your winter preparations in August. If you wait until the peak heating season (October 15th – April 15th) to address any issues, you might find yourself on a long waiting list for parts or service, leaving you and your building in the cold.

Therefore, summer preventative maintenance is not just a good idea—it’s a necessity. It sets the stage for a trouble-free, efficient heating system that will serve you well throughout the winter months.

Assessing Your Heating Coils Before Winter

Assessing Your Heating Coils Before Winter

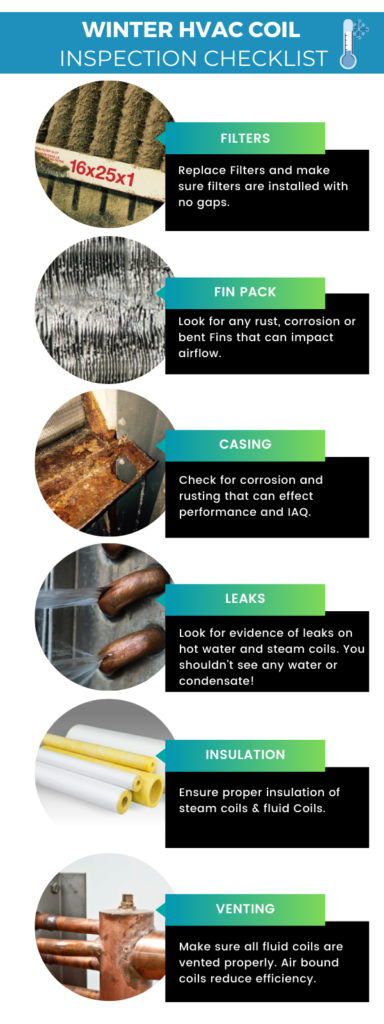

What You’ll Want to Inspect…

As the weather cools, it’s important to make sure your heating coils (hot water coils and steam coils) are in good condition.

When looking for common problems with your heating coils, it is important to inspect the filters and replace them if necessary. Make sure there are no gaps between filters when installed. You should also take note of corrosion and rust on the fin pack, as well as any bent fins that can impact airflow. Further, check for evidence of leaks on hot water and steam coils and ensure proper insulation of steam coils and fluid coils. Lastly, make sure all fluid coils are vented properly as air bound coils reduce efficiency.

How to Prevent External Fouling & Freezing from Affecting Your HVAC Coils

The Detrimental Effects of Fouling and Corrosion on HVAC Coils

Fouling and corrosion are two major threats that severely impact the performance and longevity of HVAC coils.

Fouling refers to the accumulation of dirt, dust, and debris on the coil surfaces. This typically happens when the fin pack becomes dirty over time due to exposure to environmental pollutants. When cleaning is attempted without proper care, it can further compact the dirt into the fin pack, leading to fin degradation. It’s a destructive process that decreases the coil’s overall heat transfer ability.

Corrosion, on the other hand, is the gradual deterioration of metal caused by a chemical reaction with the environment. This is commonly seen as rusting, which can occur due to factors like moisture, humidity, or exposure to certain chemicals.

Both fouling and corrosion have a negative domino effect on the HVAC system. Reduced airflow caused by dirt-impacted fins and corroded surfaces diminishes the system’s performance. This leads to the system working harder to achieve the desired temperature, consequently consuming more energy and significantly increasing operational costs. Furthermore, these issues shorten the system’s lifespan, resulting in frequent and costly replacements. Understanding and addressing fouling and corrosion in HVAC coils is crucial to maintaining an efficient and cost-effective heating system.

Addressing External Fouling and Corrosion: Key Considerations

Understanding the detrimental effects of fouling and corrosion is only part of the battle. It’s equally essential to explore strategic solutions to combat these common issues effectively, to ensure the longevity and efficacy of your HVAC system.

Firstly, if your heating coils exhibit extensive fouling or corrosion, they may be beyond salvaging. In this case, ordering a replacement coil is your best course of action. Facilities must ensure they make this decision in good time to avoid peak season delays and unplanned downtime.

When ordering a replacement coil consider using heavy-duty materials such as stainless steel for durability. Stainless steel coils are particularly resistant to corrosion, providing a robust solution for environments with high humidity. Protective coil coatings can also help to extend the lifespan of your coil, while improving clean-ability and performance. Coated coils are ideal for protecting coils in corrosive environments and coils with high UV exposure such as pharmaceutical and medical facilities, industrial manufacturing plants, and coastal environments.

Lastly, introducing UV light disinfection in front of the HVAC coils is an innovative solution to consider. UV light can effectively kill biological contaminants such as mold and bacteria, reducing coil cleaning and significantly extending the coil’s life. Moreover, it can increase coil efficiency by mitigating the risk of fouling, leading to a more effective and energy-efficient heating system.

Remember, the key to a long-lasting, efficient HVAC system lies not only in regular maintenance but also in strategic preventive measures. By addressing fouling and corrosion proactively, you can ensure your system is ready to serve you effectively and efficiently throughout the challenging winter season.

The Damaging Impact of Frozen HVAC Coils

Freeze damage poses a significant threat to coils, an issue that can severely impair their performance and longevity. This phenomenon occurs when the fluid within the coil freezes, expanding and generating pressure that the coil isn’t designed to handle. The resultant stress can cause the coil tubes to rupture, making the coil ineffective and requiring replacement.

Protecting Your HVAC Coils from Freeze Damage

During your summer preventative maintenance, it’s crucial to inspect the operation and setpoints of your freeze stat— a safety device that prevents freezing within your HVAC system. It is also advisable to drain all water from your coils that will not be in use, or to fill them with glycol. This can be achieved by using compressed air or dry nitrogen to ensure no residual water is present. It’s important to note that improperly drained coils can freeze, leading to costly damages and system downtime.

However, while glycol can prevent freezing, it can also degrade the coils, causing early corrosion, and reducing coil lifespan and efficiency. In this context, utilizing Freeze Block technology when ordering replacement coils can be a game-changing solution.

Freeze Block technology is an energy-saving alternative to glycol that can effectively protect your coils from freeze damage, even in the event of a freeze stat or power failure. It offers the added advantage of potentially reducing the need to drain coils, saving time, and reducing maintenance costs. This innovative technology provides true peace of mind during the winter months, ensuring that your heating system operates efficiently and effectively, regardless of external conditions.

Take Action and Secure Your HVAC System Against Fouling, Corrosion, and Freeze Damage Now!

Taking proactive steps to combat fouling, corrosion, and freeze damage can significantly extend the lifespan of your HVAC system while ensuring optimal performance and reliability all winter long. At Cooney Coil & Energy, we are committed to providing solutions tailored to meet your specific needs. Contact our team today!