Why Steam Training is a Game-Changer

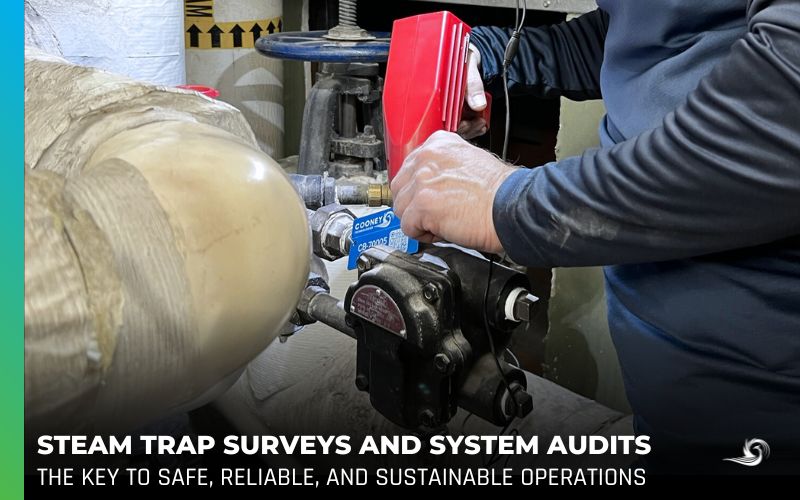

Steam systems can be a maintenance team’s best friend—or their biggest headache. From leaks and safety concerns to the lack of formal training, the challenges are real. Yet, when properly maintained, steam remains one of the most reliable and energy-efficient heat transfer solutions available.

Ready to elevate your steam expertise? Join our one-day Watson McDaniel training course, designed to provide you with practical tools and knowledge to optimize your system, overcome common challenges, and enhance equipment performance.

Whether you’re installing Watson McDaniel products, servicing competitor systems, or troubleshooting complex issues, this course has everything you need to succeed.

Why This Course Matters

Understanding steam systems doesn’t just improve performance—it enhances safety, streamlines operations, and reduces costs.

By attending this course, contractors, maintenance personnel, service technicians, and sales representatives will gain hands-on experience and a clear understanding of key steam system concepts. With both classroom education and live product demonstrations, attendees will leave prepared to apply best practices in the field immediately.

What You Will Learn

Our course curriculum is designed with both utility and practicality in mind, covering the following essential topics:

- Steam Essentials

Learn how latent heat, BTU calculations, and pressure-volume relationships impact steam system performance. Understand the principles of heat transfer and mitigate velocity and noise issues.

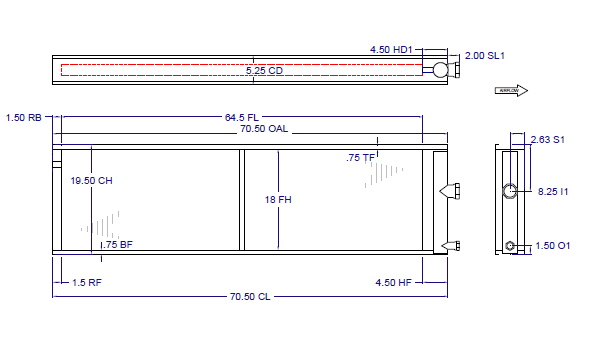

- General System Piping Guidelines

Discover piping best practices to improve efficiency and prevent costly mistakes.

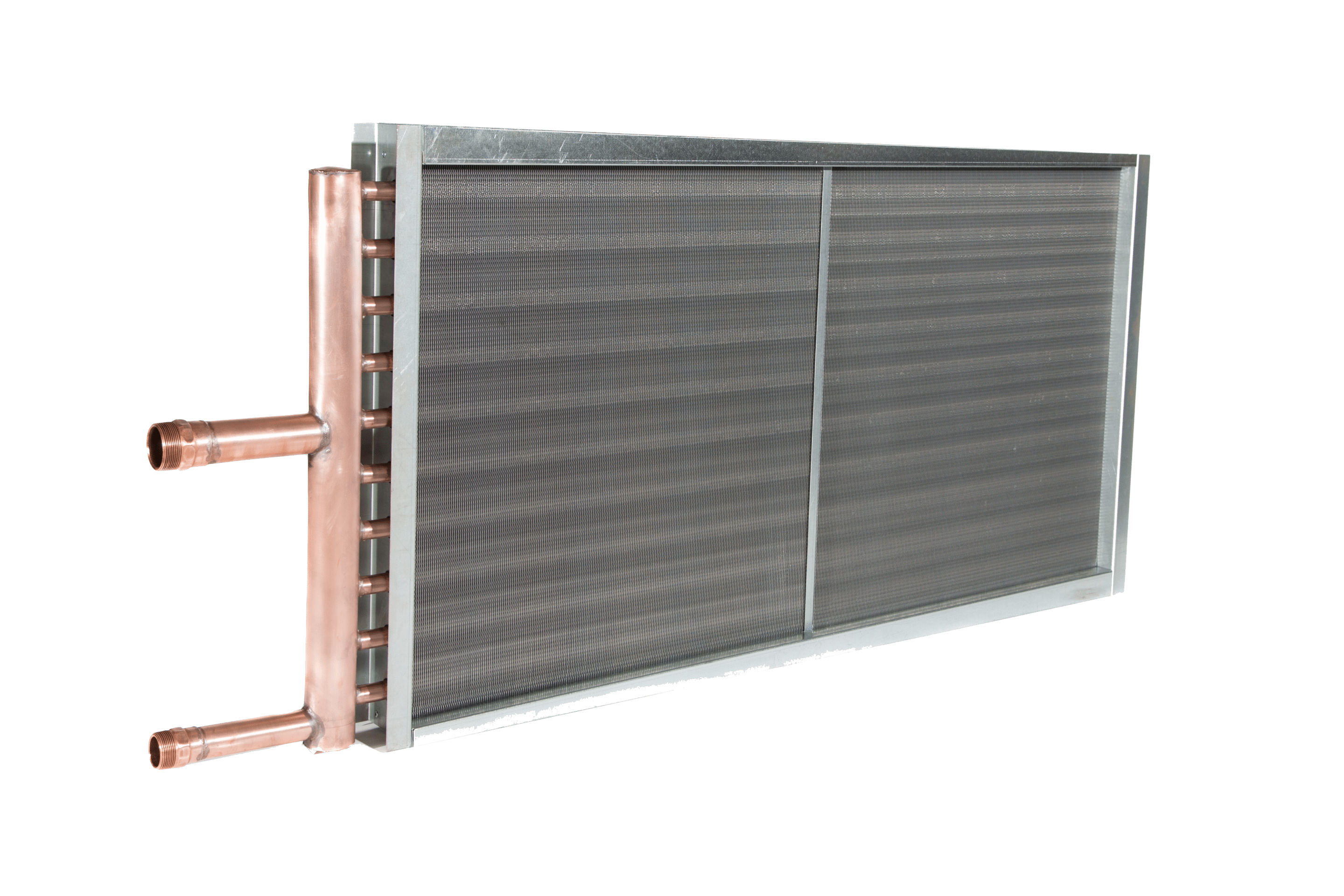

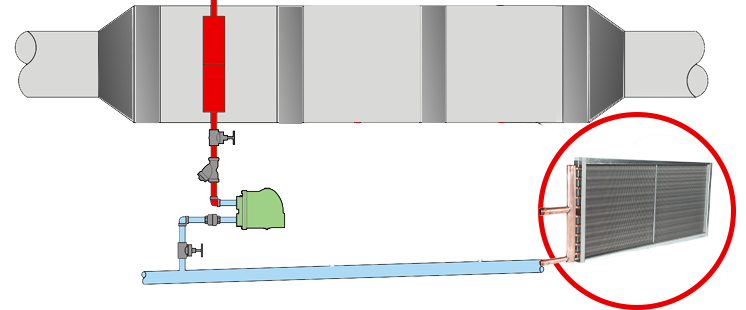

- Applying Steam Equipment Properly

Explore case studies and principles for selecting and using steam distribution and steam-consuming equipment effectively.

- Extending Product Life

Gain valuable tips for maintaining long-term performance while preventing common failures.

- Troubleshooting Fundamentals

Diagnose and resolve product and system-related issues with confidence.

Condensate Recovery Best Practices

Unlock the benefits of using electric or pressure-motive pump packages for efficiency-boosting condensate recovery.

- Live Products & Hands-On Training

Engage directly with live demonstrations and operating steam system in the training facility.

Build Confidence & Optimize Performance

This course bridges the gap between theory and application, making it an invaluable experience for anyone working in or around steam systems. Whether you’re maintaining steam traps or optimizing condensate return systems, the tools and knowledge gained here are designed to improve your facility’s efficiency, safety, and overall effectiveness.

Don’t wait to elevate your expertise! Reserve your spot today and build your confidence with steam .