Navigating Winter Coil Replacement in the Dead of Winter

Winter presents a unique set of challenges for facility managers and mechanical contractors, including unexpected coil replacement. Here at Cooney Coil & Energy, we’re more than just a company; we’re your friendly expert guide through these icy obstacles.

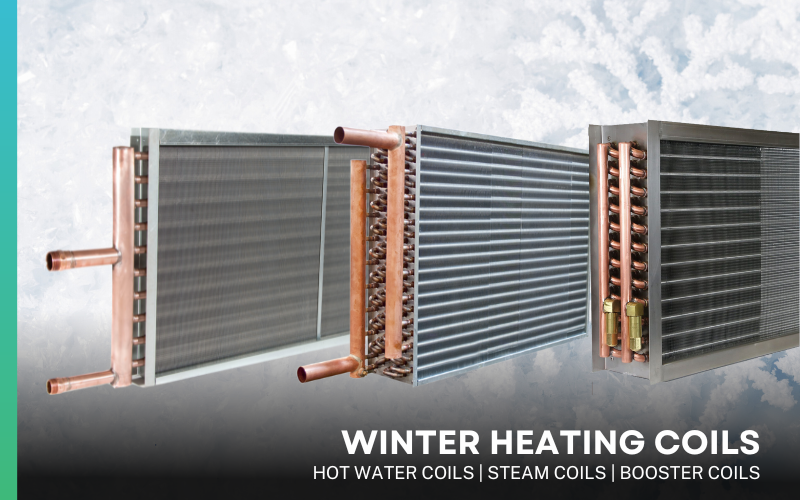

Understanding Winter Heating Problems

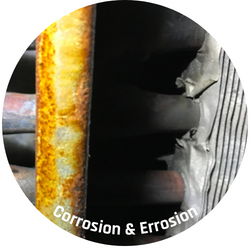

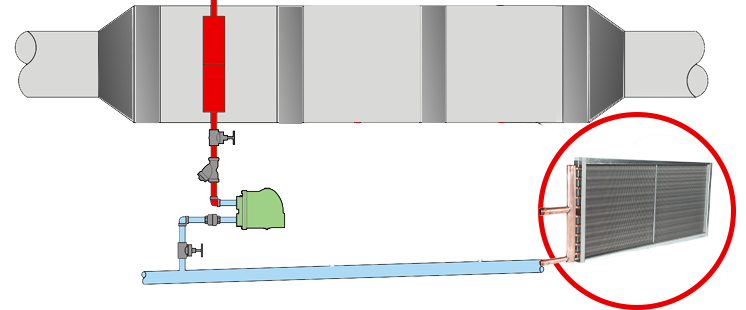

From frozen coils to malfunctioning heating systems, the winter season can be harsh on your HVAC systems. And it’s not just about keeping people comfortable indoors. Inefficient or damaged heating coils ramp up your overall heating costs, and in the worst-case scenario, can freeze and split leading to water damage or rendering your facility unusable until repairs are made.

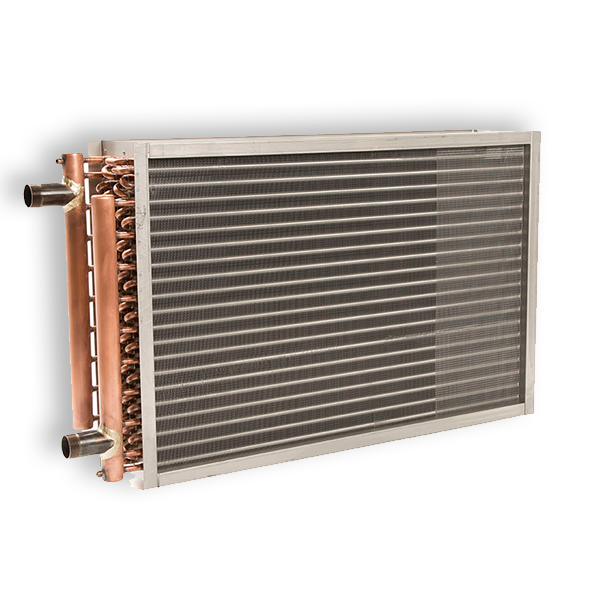

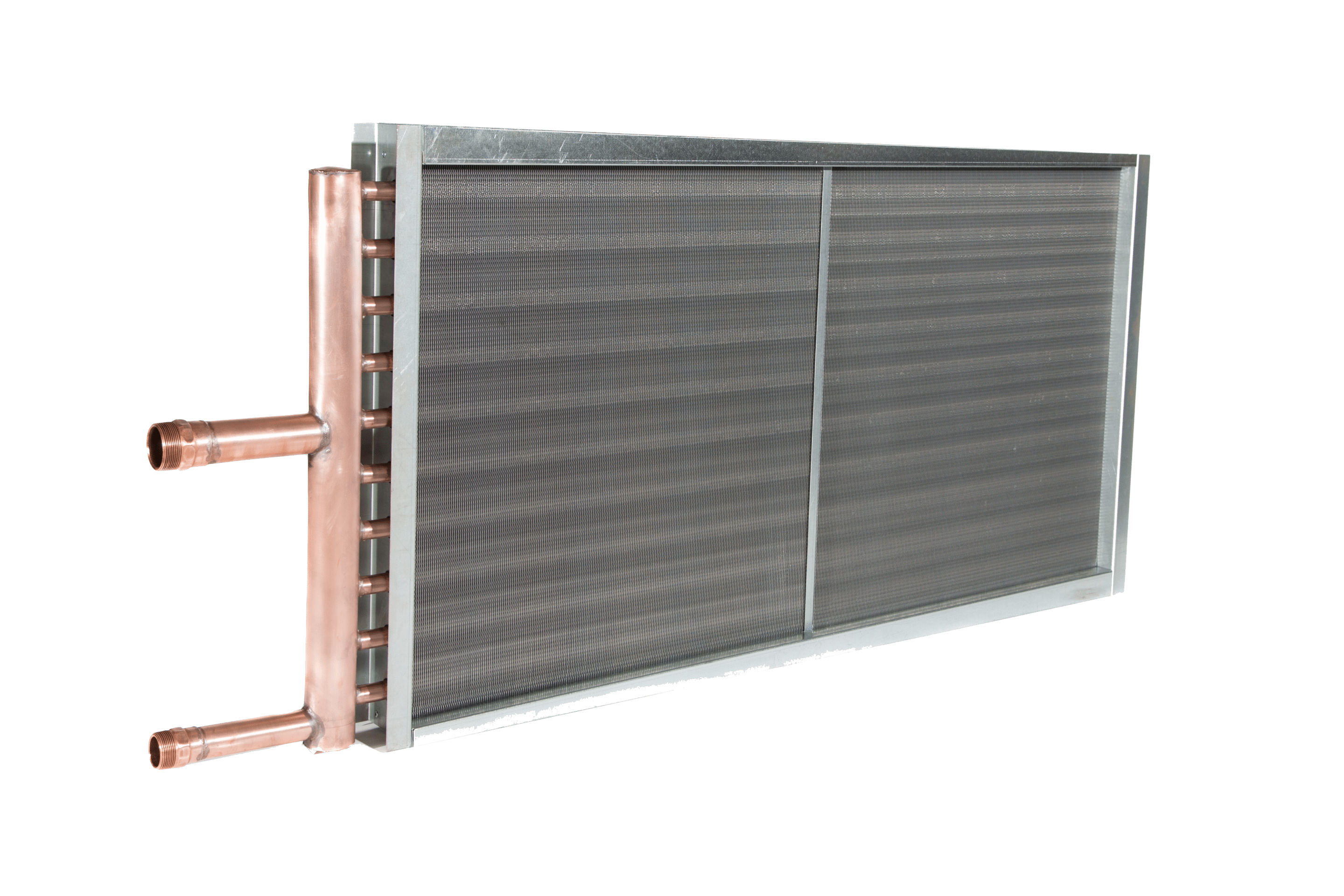

Hot Water Coil Solutions

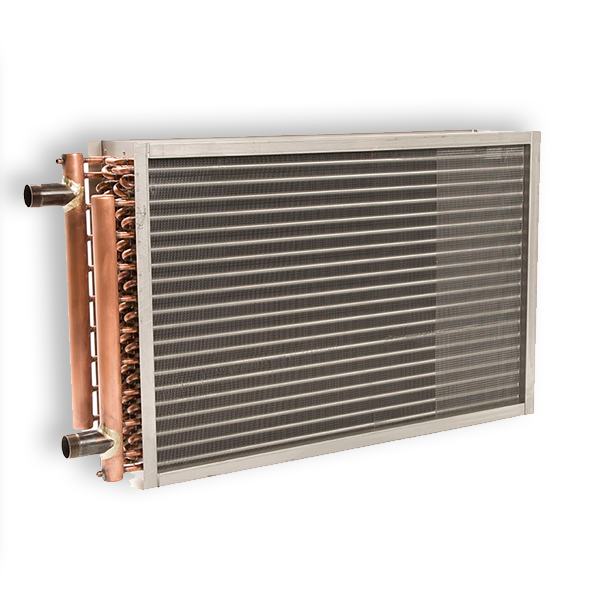

We offer a wide variety of heating coils to meet your needs, including hot water coils, steam coils, and steam distributing coils. Our top-selling replacement hot water coils are widely used in commercial applications, fitting models from Carrier, Trane, Heatcraft, York, Daikin, McQuay, and others. Our extensive database of steam, hot water and booster coils includes part numbers, prices, and performance data, making it easier for you to find the best replacement coils anytime you need.

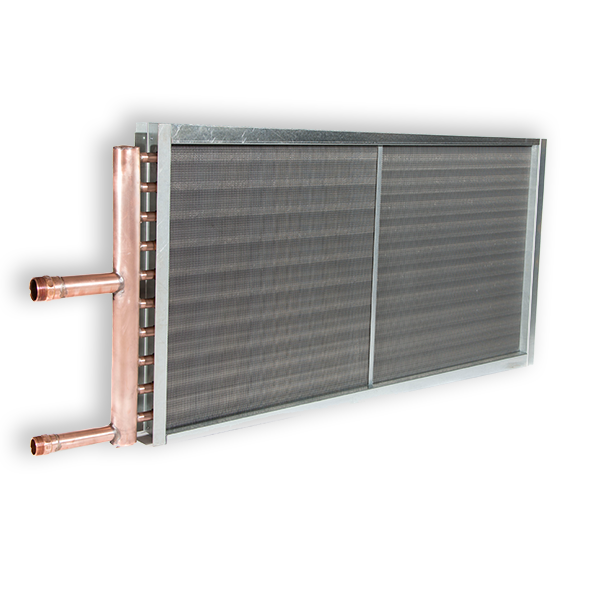

Replacement Steam Coils

At Cooney Coil & Energy we offer two types of steam coils: standard and distributing. While distributing coils, often referred to as non-freeze steam coils, are designed for colder climates, they can still freeze under extreme conditions. We offer steam coils with tubes made of copper, cupro-nickel, carbon steel, and stainless steel, catering to various temperature requirements and levels of corrosion resistance. Our coils include steam coils suitable for Armstrong, Heatcraft, Aerofin, Colmac, and other systems. Ask us about our patented Freeze Block Steam coils for added peace of mind this winter.

Why Wait? Replace Your Heating Coils Today

Instead of waiting for an emergency situation to arise, why not order your replacement heating coils today? We offer both standard and custom heating coils, ensuring that you get the right fit for your specific needs.

Our unique ‘Form, Fit & Function Guarantee’ sets us apart from other companies in the industry. When we specify a replacement part, we guarantee its perfect fit and operation. No guesswork, no surprises. Just the right part, working exactly as it should.

We’re committed to giving you the best value for your investment. That means competitive pricing on all our HVAC replacement parts. But it’s not just about price—it’s also about choice. Our extensive product range ensures you can find the right solution for your specific system.

Get In Touch with Cooney Coil & Energy

Navigating winter heating issues doesn’t have to be a daunting task. With proactive maintenance, quality parts, and a little help from your friends at Cooney Coil & Energy, you can keep your systems running smoothly all winter long. After all, we’re here to provide expert services, quality HVAC parts, and, most importantly, a friendly, down-to-earth approach to customer service.

Ready to tackle your heating issues head-on? Contact us at 610-783-1136 or [email protected] We’ve got you covered, no matter how cold it gets.

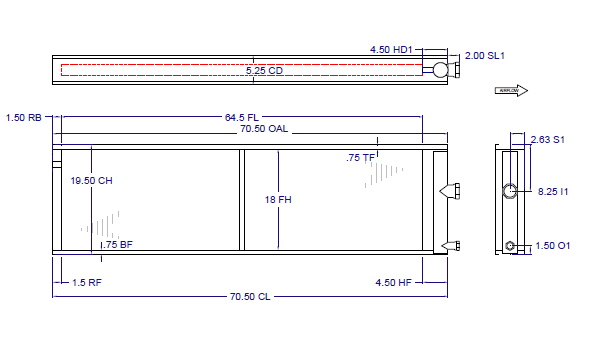

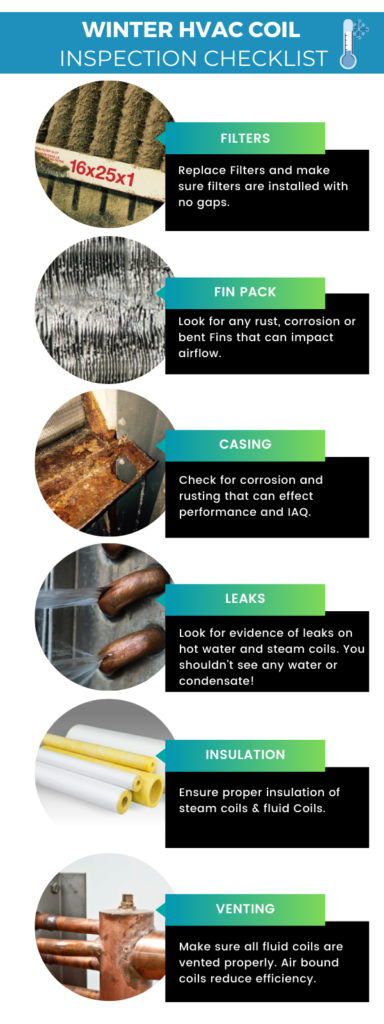

Site Visits

On our site visit, we’ll take measurements, understand your system, identify challenges, and suggest solutions.

Assessing Your Heating Coils Before Winter

Assessing Your Heating Coils Before Winter