With the heavy demand on hot water, chilled water, steam, and refrigerant coils, proper maintenance is essential—not just for efficiency but also to prevent unexpected breakdowns during the peak of summer. Getting a jump on maintenance now can help you avoid delays, costly emergency orders, and the headache of replacing a coil when you need cooling the most. Follow our coil maintenance checklist to keep your system running at peak performance.

Understanding Different Types of Cooling Coils

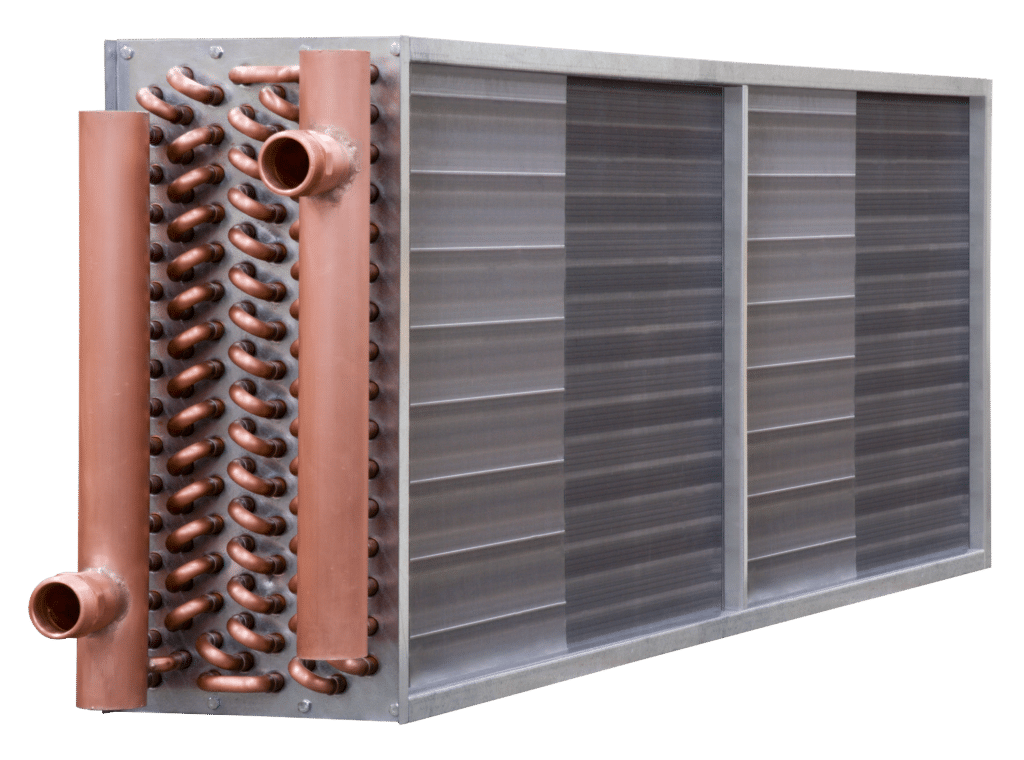

Chilled Water Coils

Chilled water coils cool the air by circulating chilled water through the coil. They can be constructed with different numbers of rows, typically between 3-10, affecting their depth and efficiency.

Direct Expansion (DX) Coils

DX coils cool air directly by circulating refrigerant through the coil. Unlike chilled water coils, these require a refrigerant distributor instead of a hydronic feed, making them ideal for refrigeration systems.

Cooling Season Prep

1. Inspect Coils for Damage & Debris

Before turning up the cooling, give your coils a thorough inspection:

- Look for dirt, corrosion, or bent fins.

- Use a fin comb to straighten any bent fins. If extremely smashed or bent, you’ll want to order a new coil to avoid performance loss.

- Check for leaks, especially around connection points.

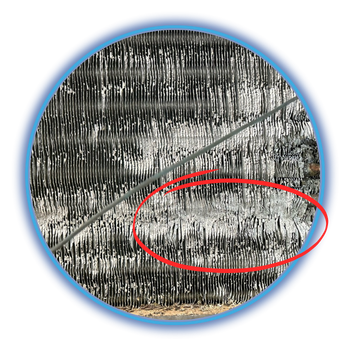

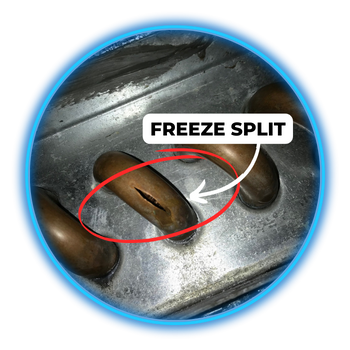

- Inspect chilled water coils for freeze damage.

Bulged and split areas, especially at the return bends, indicate past freezing issues. These often go unnoticed in winter when the coils aren’t in use. Learn more about why fluid coils freeze and how to prevent it: Read here

Bulged and split areas, especially at the return bends, indicate past freezing issues. These often go unnoticed in winter when the coils aren’t in use. Learn more about why fluid coils freeze and how to prevent it: Read here

Pro Tip: Regular inspections help catch minor issues before they turn into costly repairs.

2. Check and Replace Coils

Sometimes, coils become damaged or inefficient over time. Old or failing coils can lead to higher energy bills and decreased cooling performance. Replacing HVAC coils before the cooling season is crucial to stress-free summer cooling.

Cooney Coil & Energy can design and manufacture replacement coils for any HVAC system. Our Form, Fit & Function Guarantee ensures that our replacement coils fit accurately and function seamlessly. Need a quick replacement for a critical area? We offer expedited coil production and shipping options, including 2-day, 5-day, and 10-day services. Call our team for availability at (610) 783-1136.

3. Clean Coils and Drain Pans

Dirty coils can strain your system, leading to higher energy costs and reduced performance. Cleaning your HVAC coils and drain pans before the cooling season is essential for optimal functioning:

- Remove dust and debris to enhance heat transfer.

- Flush drain lines with a disinfectant or vinegar-water mixture to prevent clogs and water damage.

- Ensure proper airflow by keeping coils free of obstructions.

Did You Know? Clean coils can improve energy efficiency by up to 30%!

4. Verify Refrigerant Levels

For facilities using refrigerant coils, ensuring the correct charge is essential. If your system isn’t cooling effectively, check for:

- Refrigerant leaks

- Proper pressure levels

- Correct charge

Reminder: Only licensed professionals should handle refrigerant recharges and leak repairs.

5. Inspect Fans & Airflow

Ensure your system is moving air efficiently by:

- Checking condenser and evaporator fan motors.

- Listening for unusual noises.

-

Ensuring no obstructions are blocking airflow.

Cooney Coil & Energy’s Cooling Coil Solutions

Guaranteed Fit

Experience seamless installation with our Form, Fit Function Guarantee, ensuring every coil fits perfectly and operates flawlessly.

Engineering Excellence

Our team is made up of heat transfer specialists! We can help with calculations, drawings, and HVAC performance.

Wide Coil Selection

Choose from a diverse range of coils, including DX, refrigeration, and chilled water options, tailored to meet your specific needs.