Avoid Winter Breakdowns with Coil Prep

Fall Coil Replacement Guide

Heating season is right around the corner, which means now’s the time to check your HVAC coils. These are the workhorses that move heat and keep your system running efficiently. If they’re neglected, you could be looking at mid-winter breakdowns, expensive emergency fixes, and unhappy building occupants.

This guide gives facility managers, contractors, and engineers practical tips on coil inspections, replacements, and system prep before winter hits.

HVAC Coil 101 | Why Inspections Matter

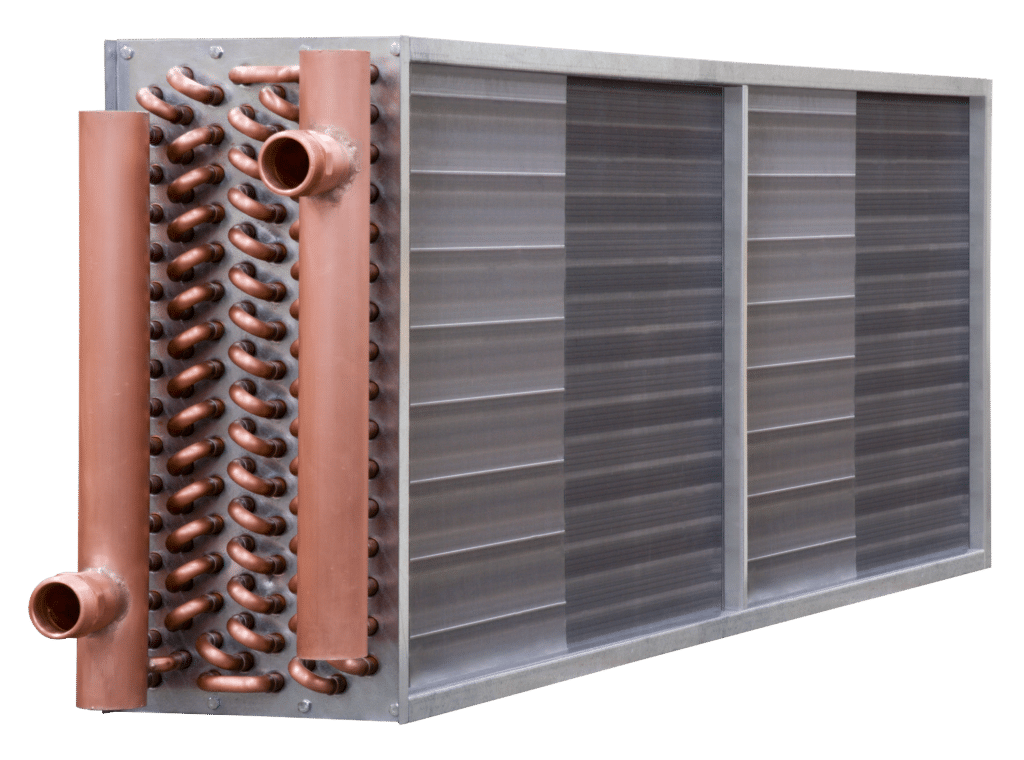

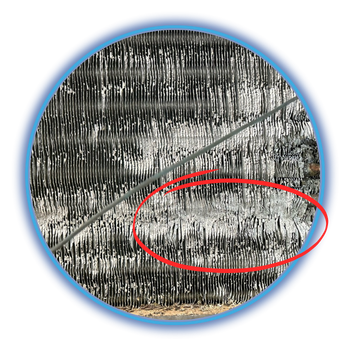

Coils are the heat exchangers in HVAC systems. When hot water, steam, or refrigerant flows through the tubes, the fins transfer heat to or from the air. If coils are dirty, corroded, or leaking, efficiency drops and supporting equipment works harder. This drives up costs and strains other equipment like boilers and chillers.

What to look for in fall inspections:

-

Visible leaks, rust, or corrosion

-

Reduced heating or cooling output

-

Frequent refrigerant or steam loss

-

Uneven room temperatures

-

Repeated service calls on the same coil

If you notice these warning signs, it’s time to call in a coil expert. At Cooney Coil & Energy, our team handles on-site measurements and diagnostics to make sure any replacement is the right fit, form, and function — so you don’t have to risk costly mis-measures.

Boosting Performance with Coil Upgrades

Start with maintenance

Basic maintenance goes a long way: cleaning coil surfaces, clearing debris, and replacing filters. A dirty coil can increase energy use by 20% or more, so these small steps quickly pay for themselves.

When replacement is the smarter move

If a coil is badly corroded, leaking, or past its service life, replacement is usually more cost-effective than repair. Most coils are built to order, so planning ahead avoids rush shipping or emergency downtime in January.

Upgrade opportunities

When replacing, consider enhancements that improve system performance and reliability:

-

Protective coatings to resist corrosion

-

Material upgrades (e.g., copper for tough environments)

-

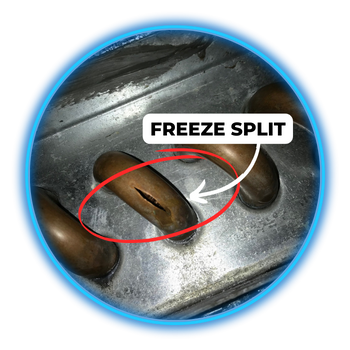

Adding Freeze Block™ technology protects hot water, chilled water and steam coils from freeze-related rupture damage.

-

Smart Coil™ systems that alert building automation systems if a freeze occurs

Heating Season Prep – Plan, Don’t Panic

Why timing matters

Fall is the ideal time for coil replacements. Systems can be taken offline without disrupting heat delivery, and coils can be ordered before the rush. Waiting until the first freeze risks costly emergency repairs, expedite freight charges, and unplanned downtime in critical facilities.

Quick prep checklist for fall

-

Replace or clean air filters

-

Test coils for leaks before startup

-

Verify valves operate properly

-

Bleed air from hot water coils

-

Inspect drain pans and condensate lines

These preventive tasks, paired with professional coil diagnostics, ensure your HVAC system is primed for winter.

Conclusion

Educating yourself about coil condition and acting early, is the key to a trouble-free heating season. With expert site visits, precise measurements, and fast-turnaround manufacturing, Coil & Energy helps facility teams replace coils confidently before the cold sets in.

Need guidance on a replacement or upgrade? Request a site visit today to make sure your system is winter-ready.

Coil Replacement

Frequently Asked Questions

How do I know if a coil needs replacing?

Leaks, corrosion, or repeated service calls are clear signs. A professional site visit can confirm if repair or replacement is the better option.

How long does it take to get a replacement coil?

Most coils are custom-built. Lead times vary, which is why fall is the best time to order before heating demand peaks. Give us a shout at [email protected] to learn about our current lead time and expedite options.

Can I measure coils myself?

We don’t recommend it. Precise measurements are critical, and mistakes can lead to fit or performance issues. Our team provides on-site coil measurements to guarantee form, fit, and function.

What upgrades should I consider when replacing a coil?

When planning a coil replacement, think about options that extend performance and reduce future headaches. Material upgrades, such as copper tubes or fins, improve durability in corrosive environments. Coils designed with wider fin spacing can make cleaning easier, especially in dusty or dirty applications. Protective coatings can also add a layer of defense against corrosion and extend coil life.

If freezing is a concern — or if the space is critical to your facility’s operation — Freeze Block™ technology should be considered to prevent rupture. For added visibility, Smart Coil™ systems provide freeze detection and alerts to your building automation system.