Heat Exchangers 101: What Facility Managers Should Know

Heat exchangers are an essential component in facilities and systems that require the transfer of heat from one medium to another. In most cases, that means transferring heat from a hot medium (such as steam) to a cold fluid (like water).

But how does it work? And more importantly, which type of heat exchanger is best suited for your facility? Let’s break down some of the basics.

Types of Heat Exchangers

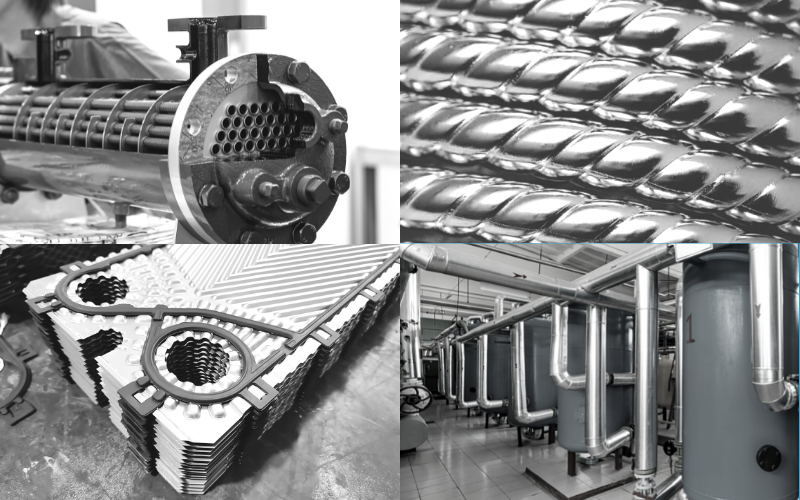

Heat exchangers come in many shapes and sizes, each designed to handle different levels of pressure, temperature, and flow rate There are four main types of heat exchangers: Hot Water Storage Tanks with Steam or Hot Water Immersion bundles, Plate & Frame, Shell & Tube, and Shell & Coil. Let’s take a look at the key differences between these types of heat exchangers:

Hot Water Generator Storage Tanks with Steam or Hot Water Immersion Bundles

These hot water generator / storage tanks have been popular with facilities for many, many years. They have been typically used for generating domestic hot water for the facility using either a steam immersion bundle or 180F heating hot water bundle in a large vertical or horizontal storage tank. Circulation pumps are used to assist in the recovery rate of the hot water and also maintaining the proper hot water set temperature throughout the system. They provide a large buffer amount of available hot water.

These storage tanks take up a large footprint and energy efficiency suffers by keeping the large volume of water (1500 gallons or more) at the desired temperature even at times of minimal actual usage. Unheated, stratified potable water in this system may be susceptible to Legionella concerns, especially in healthcare facilities. Leaking immersion bundles require rapid attention to prevent possible water contamination or flooded condensate systems.

Plate and Frame Heat Exchangers

Plate and frame heat exchangers are a common type of heat exchanger used in industrial applications. This type of heat exchanger consists of several metal plates sandwiched together with gaskets between each plate. The plates create separate channels for each fluid to flow through; as one fluid passes over the plates it absorbs the heat from the other fluid. Plate and frame heat exchangers can be used for both heating and cooling processes for facilities that need to maintain steady temperatures year-round. Be careful using these with steam applications as the gaskets often get worn out due to the high temperatures and can cause leaking. If used with improperly filtered water, the tight fluid pathways in the plates may clog and decrease heat transfer dramatically.

Shell & Tube Heat Exchangers

Shell and tube heat exchangers are another type of commonly used industrial and commercial grade heat exchanger. These consist of a tube bundle contained within an outer shell; one fluid flows through the tubes while another medium (typically steam) flows around them in the shell space.

Shell and tube heat exchangers are fairly efficient; they can handle large volumes of both hot and cold fluids simultaneously while providing very good temperature control. This makes them ideal for applications where precise temperature control is needed. A disadvantage to shell & tube heat exchangers is their large footprint which can make maintenance difficult if repairs are needed to the tube bundle. Other concerns may be, pull space for bundle replacement and flash steam in the condensate system.

Shell & Coil Heat Exchangers

Shell & coil heat exchangers are similar to shell & tube units but with several distinct advantages — they offer more compact designs, improved portability, higher levels of thermal efficiency, faster response times, lower pressure drops across the unit, quieter operation, easier maintenance access, and increased durability due to fewer components than traditional designs have.

While fully-welded stainless steel shell & coil units may not be as widely used as hot water generator or storage tanks, plate & frame or shell & tube units yet, these advantages make them well worth considering if you need a reliable yet highly efficient source of thermal energy transfer in your facility.

Heat exchange is an important part of any facility manager’s job because it can help increase efficiency while lowering costs associated with energy usage. These four main types of heat exchangers each offer their own unique set of advantages depending on your application needs. By understanding which type best suits your needs, you can ensure that you get maximum performance out of your thermal energy transfer equipment while reducing operational costs over time. It pays to do some research on which type would work best in your situation so you can maximize its potential benefits for your facility’s operations!

Need help selecting a heat exchanger? Give our team a call today at (610) 783-1136!

Looking for a New Heat Exchanger?

At Cooney Coil & Energy, we offer a variety of heat exchangers for all types of applications.

Unsure of what you need? Give our team a call at (610) 783-1136 to schedule a site visit and consultation today.

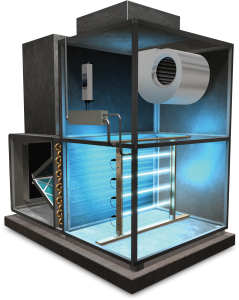

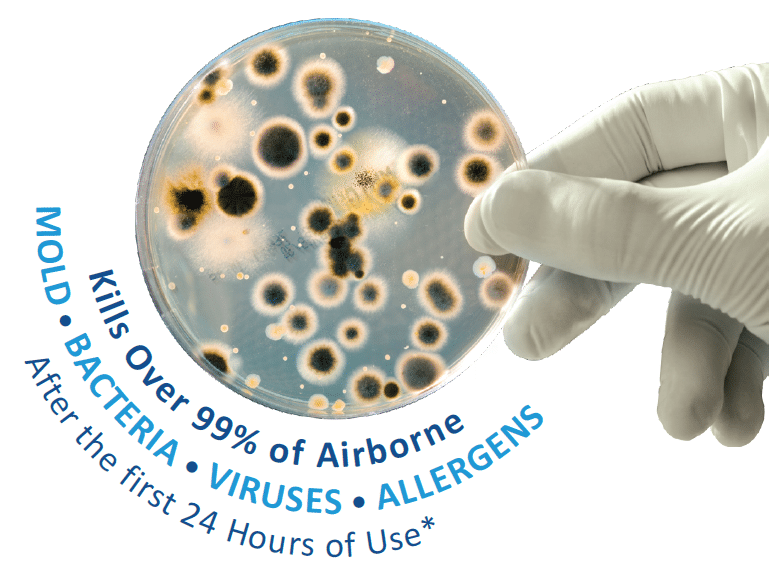

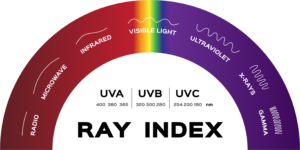

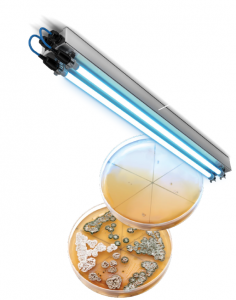

Ultraviolet light, also known as UV light, is a part of the electromagnetic spectrum. There are several types of UV frequencies.

Ultraviolet light, also known as UV light, is a part of the electromagnetic spectrum. There are several types of UV frequencies. disinfection machine.

disinfection machine.