When to Replace Commercial HVAC Coils

Recognizing the Signs: When You Should Replace Commercial HVAC Coils

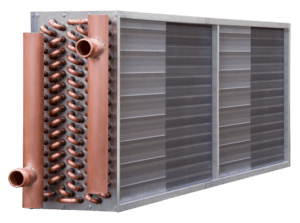

Maintaining the right temperature in your facility is essential for ensuring the comfort and safety of those living or working within. That’s why it’s important to have a properly functioning HVAC system with coils that are regularly inspected, serviced and replaced when necessary.

Unfortunately, coils can fail prematurely due to freeze damage or other factors such as incorrect selection, corrosion or lack of maintenance. Understanding the signs that indicate when it’s time to replace or repair your HVAC coils is essential for your facility.

In this article, we’ll provide you with an overview of indicators that signal it might be time to replace or repair your HVAC coils so you can keep your building comfortable and safe at all times. Let’s get started!

Reduced System Efficiency

A decrease in system efficiency is often the first sign that your HVAC coils may need to be replaced or repaired. If you notice an increase in energy consumption without significant changes in usage patterns, this can indicate a problem with your coils. In addition, if any areas of your building are not being adequately heated or cooled, this could also indicate a problem with your coils.

Frequent Breakdowns and Repairs

If you’re experiencing frequent breakdowns and repairs with your HVAC system, it’s time to evaluate whether coil replacement or repair is the most cost-effective solution. The costs associated with regular repairs can add up quickly, making it more financially sensible to invest in replacing the coils entirely.

Be sure to evaluate the cost of repairs versus replacement before making your decision. Doing so will help ensure that you are investing in the most suitable solution for your facility’s needs.

Visible Coil Damage or Corrosion

Corrosion is another indicator that your coils may need to be replaced or repaired. If you notice any signs of corrosion, it’s important to address the issue as soon as possible. Corroded coils can cause significant problems if left unchecked, including reduced efficiency, system damage and potentially even health and safety risks.

If you notice any physical damage, including cracks, leaks, bulged or split return bends, these are strong indicators that the coil should be replaced. Freeze damage is one of the most common reasons for premature coil failure, it occurs when water turns into ice, increasing its volume and creating pressure on the coil. This pressure is strong enough to rupture the coil, resulting in a bulged and split return bend or fin pack. By adding Freeze Block technology to your coils when replacing, you can reduce the risk of freeze damage and avoid costly repairs or replacements. It is important to check your HVAC system on a regular PM schedule for any signs of visible damage or corrosion in order to avoid costly repair fees later on.

Poor Airflow

If you notice a decrease in airflow or an overall decrease in circulation, this could be a result of clogged fins on the coil. This can lead to uneven temperatures within the building, as well as an uncomfortable environment due to inadequate air movement.

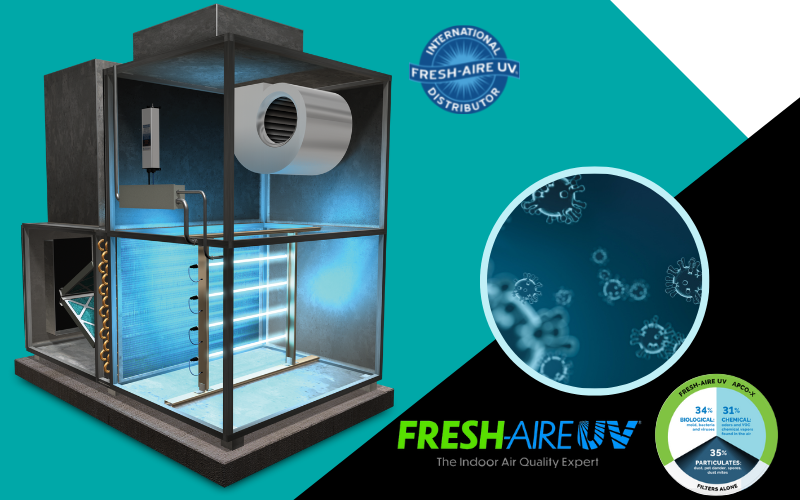

Properly cleaning coils is essential for maintaining their efficiency and prolonging their lifespan. Additionally, the use of UV systems can help reduce microorganism growth that can lead to increased dirt and dust buildup on the coil surface, negatively impacting air quality within your facility. By installing a UV system along with regular maintenance on your coils, you will be able to improve the overall airflow and reduce the need for frequent coil repairs or replacements. This in turn will help you save on energy costs, maintain comfortable temperatures and ensure that your equipment is running at optimal levels.

Age of Existing Coils

If your coils are older than 10 years, it’s time to consider replacing them. Efficiency can drop by 30% over time. This is because, as time passes your HVAC coils will naturally weaken due to constant expansion and contraction. This can lead to a decrease in the coil’s performance and an overall reduction in system efficiency.

At Cooney Coil & Energy, we strive to provide reliable and cost-effective solutions for all your HVAC needs. Our team of professionals can help you evaluate your system and identify any potential issues with the coils. We offer free site visits as well as detailed diagnostics of your existing coils in order to determine if replacement is necessary.

We can provide you with the best options for replacing your heating or cooling coils and we take pride in delivering high-quality, energy-efficient products. Our experienced team is here to help you every step of the way so that you can have peace of mind knowing that you are getting the most out of your HVAC system. Contact us today for more information about our services.

Trust Cooney Coil & Energy for Your HVAC Coil Needs

Maintaining your HVAC coils is an important part of keeping your system running optimally. Signs such as visible damage or corrosion, poor airflow, and age can help you determine when it’s time to replace your existing commercial hvac coils. Regular maintenance and the use of UV systems can help reduce dirt and dust buildup, and Freeze Block coils can prevent freeze damage. At Cooney Coil & Energy, our experienced professionals are here to provide you with reliable solutions for all your HVAC needs. Contact us today for more information!