Maximizing Coil Efficiency with Ultra Violet Light

Have you ever thought any of these: “Coil cleaning and maintenance is such a hassle!…,” “My heat transfer efficiency is dropping, how can I get it back to where it used to be?,” or “We’ve got a nasty smell, what can we do to eliminate it?”?

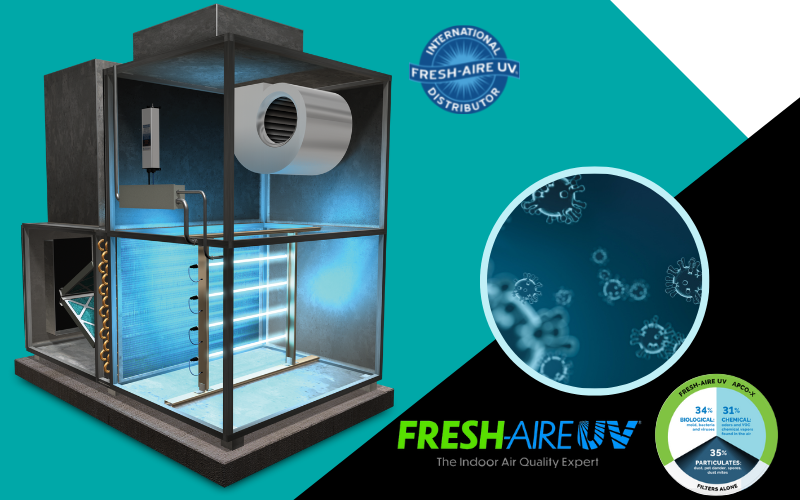

Fortunately, Cooney Coil & Energy has a solution for you! The use of ultraviolet light has a multitude of benefits including:

- Improved indoor air quality

- Increased overall health and productivity

- Increased system efficiency

- Reduced energy and maintenance costs

- Elimination of coil cleanings

- Longer system life by keeping HVAC systems microbial-free

- Less likelihood for drain lines to clog (drain pan water is completely disinfected)

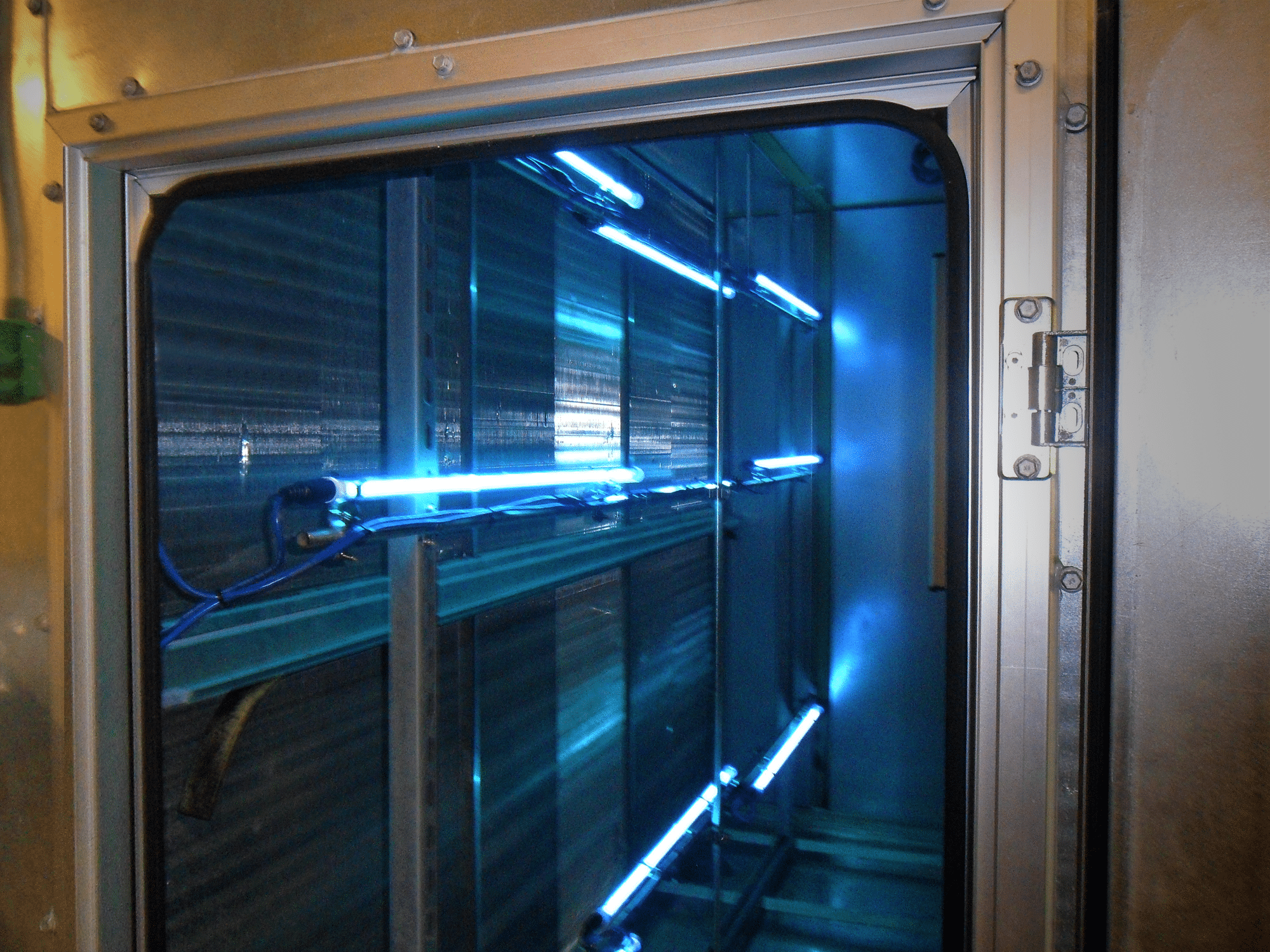

So What is Ultraviolet Light and How Does It Work?

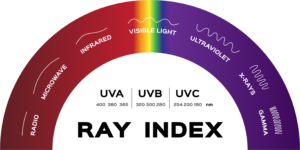

What is Ultraviolet Light? Ultraviolet light is invisible to the human eye. It is part of the electromagnetic spectrum that lies beyond the purple range of the visible spectrum. The ultraviolet (or UV) spectrum has wavelengths between 100 and 400 nanometers (nm).

The UV spectrum is further divided into wavelength ranges named UV-A, UV-B, and UV-C. By utilizing the UV-C range of UV light, germicidal benefits, as well as others, can be achieved.

How UV Light Works:

Ultraviolet technology is a non-chemical approach to disinfection. In this method of disinfection, nothing is added which makes this process simple, inexpensive, and requires very low maintenance. UV is an effective method of killing a broad range of microbes. As organic contaminants come into view of the UV light source, the UV light waves penetrate the membrane and nucleus of microorganisms, breaking the molecular bonds in the organisms’ DNA. This destruction of the DNA kills the microbe or inhibits its ability to reproduce, allowing you and your HVAC system to reap the benefits listed above!

Skeptical?

Read this case study done at Florida Hospital:

A UVC light was installed in AHU #107, a 27-year-old, 6,000 cfm unit located at the main Orlando campus. AHU #107 was selected because the coil and drain pan areas had a very visible buildup of mold, and the coil was clogged to approximately 50%.

Within weeks after the UVC installation, static pressure over the coil decreased from 1.8 in.wg to just 0.7 in. wg. Air velocity over the coil more than doubled, from 230 fpm to 520 fpm. Both the coil and drain pan areas looked absolutely clean, with no more visible evidence of mold or organic buildup. The air exiting wetbulb temperature from the AHU also decreased significantly, from 57° F (before UVC) to 53° (with UVC).

Increase in capacity calculated to be 95,245 Btuh or approximately 7.9 tons of air conditioning. Using 1 kW/ton and multiply by 24 (hours/day) by 365 (days/year) by $0.07 (electric rate), a total of $4,867 in savings is determined for this one unit. The total installed cost of the UVC lights was less than $2,000. Given the number of AHUs in the hospital, they estimated yearly energy savings well into the six figures. This estimate does not include additional savings for reduced maintenance.

The hospital is conservatively saving 15% in HVAC system energy costs, and probably much more. These results are consistent with other studies documenting that just a one-micron buildup of dirt or debris on coil surfaces can lead to a 15% loss in operating efficiency.

(data taken from a study written by Firouz Keikavousi, published in Engineered Systems Magazine)