Heat Exchangers

Shell & Coil Heat Exchangers

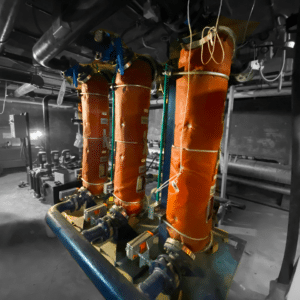

Shell & Coil heat exchanger technology is the most efficient way to generate heating hot water and domestic hot water from steam due to its ability to utilize counterflow sub-cooling. The compact vertical design of the shell & coil heat exchanger allows for installation in small spaces and tight mechanical rooms.

Want to learn more? Contact us today!

|

|

The large heat transfer surface area within the compact vertical design of the shell & coil heat exchanger allows for a large heat transfer surface area resulting in a highly efficient and effective system.

This technology is the most efficient way to generate heating hot water and domestic hot water from steam due to its ability to utilize cross-counterflow sub-cooling.

One of the key benefits of these units is that they require less frequent maintenance than traditional designs due to their robust construction and fewer components.

The stainless steel 316L welded construction of a Shell & Coil heat exchanger outperforms traditional materials like carbon steel used in shell & tube heat exchangers. With fewer welded joints than tube bundles, the possibility of leaks over time is significantly reduced. Being less prone to corrosion, the stainless steel requires minimal maintenance – a major advantage when considering long-term cost savings.

Anyone who’s been in a mechanical room knows how cramped it can get, making every inch of space precious. Therefore, the size of a new product is an important factor when considering replacements.

Traditional shell and tube heat exchangers are often designed horizontally and can become significantly large depending on the heat load, consuming valuable floor area.

In contrast, JAD shell & coil heat exchangers are designed with a compact vertical orientation. This design not only gives these heat exchangers a smaller footprint but also reduces the installation space required, potentially leading to lower installation costs.

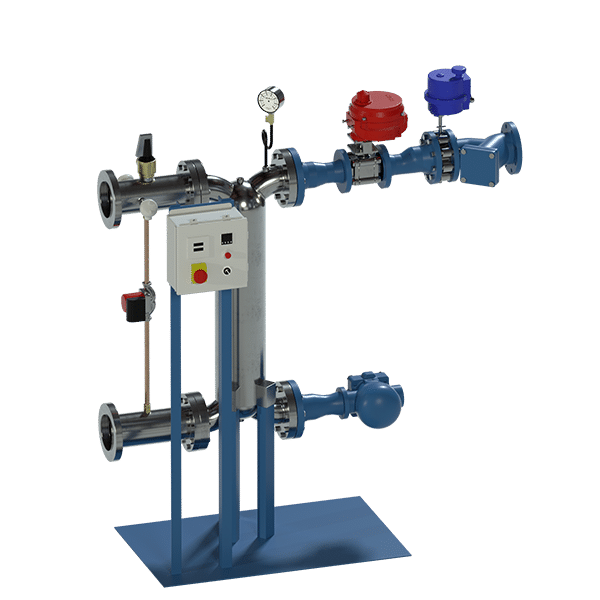

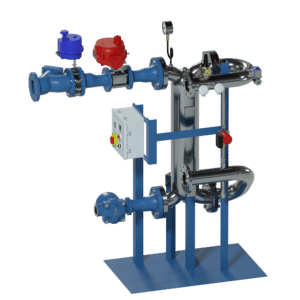

Shell & Coil Packaged Heat Exchanger

Cooney Thermo-Pack

Many customers are making the switch from shell & tube heat exchangers to shell & coil technology. Learn how the Cooney Thermo-Pack uses this technology to provide energy savings to facilities in a compact skid.

Get a Quote

Contact Us to Get Your Project Started Today

Our experienced team can help troubleshoot problems, assess complex heating and cooling system issues, and recommend the best solution. Get a hold of us today for a quote!